High-temperature fire protection

Targeted fire protection increases safety from failures on the one hand and leads to greater economic efficiency on the other. With tmax insulating cladding, temperatures of over 1000 °C can be reduced to as low as 60 °C.

Fire hazard in the engine compartment

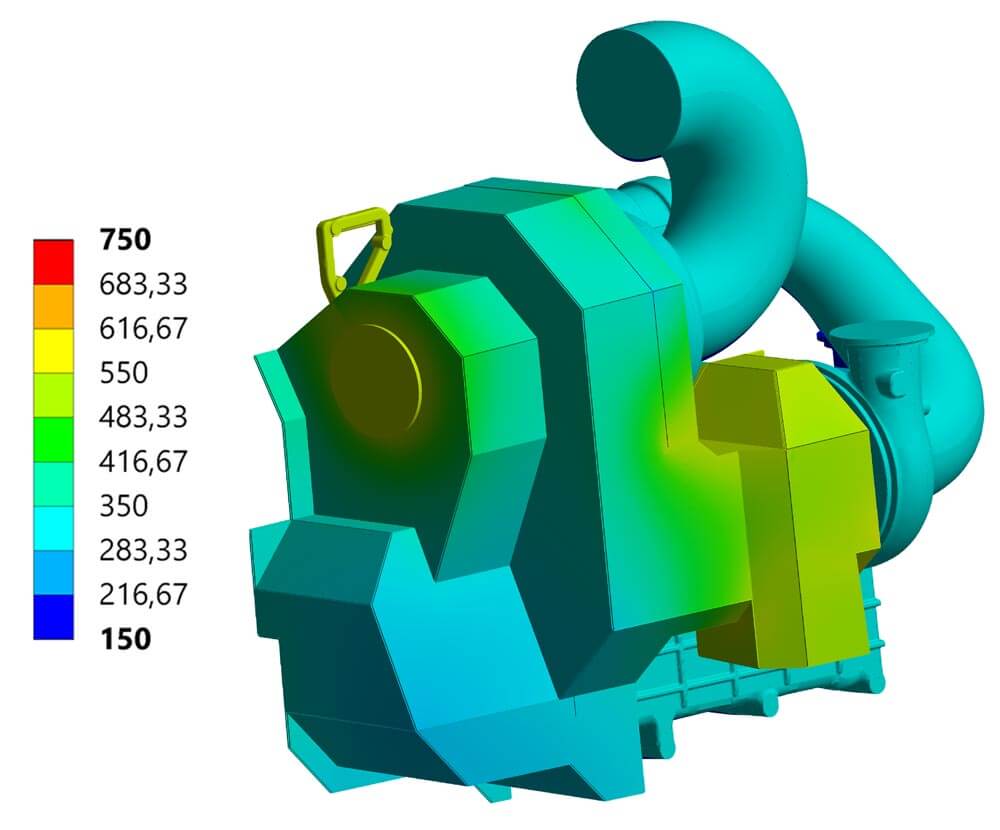

Surface temperatures of up to 850 °C can occur in the engine compartments of machines and systems. The resulting risks of fire occurrence are very diverse. A frequent cause of fire is the leakage of flammable media. In addition, easily flammable dusts and oils can also ignite on the hot surfaces when harvesters are operated.

If a fire breaks out, it is not only human lives that are in serious danger. In the same way, such an event always means an enormous loss of material assets and productivity.

These risks can only be minimized through targeted temperature management.

Contents in this e-book

How to overcome all challenges in the high temperature range.

- What are high temperature insulations?

- Where are they used?

- Requirements for high temperature insulation

- Our insulation solutions: Metallic, Foil, Textile

- Around tmax: competencies and services

Reduce fire risk, increase reliability

Optimal fire protection with tmax insulation cladding

With thermal insulation for hot surfaces and components such as turbochargers, exhaust pipes as well as manifolds, the surface temperature of all components can be reduced to below 200 °C; even down to 60 °C if required.

Fire protection for hydrogen applications

The future has a heat problem

And tmax has the solution.

In the future, hydrogen technology will play a major role not only in energy generation but also in industry and mobility. Fuel cell systems and hydrogen engines are used, for example, on ships, in trains, long-distance buses or trucks as part of the propulsion concept, as well as in combined heat and power systems to generate heat and electricity in buildings and industry.

Sometime, hydrogen technologies, which operate in the high-temperature range from 500 °C up to 1000 °C, are used. The heat that this generates can damage temperature-sensitive components and systems and consequently impair their functionality.

With high-temperature insulation from tmax, these systems are thermally insulated, and the high temperatures are thereby safely controlled.

Insulation solutions are mainly used for:

- High-temperature fuel cell systems (SOFC)

- Hydrogen internal combustion engines (HICE)

- Stationary fuel cell heating systems

- Hydrogen reformer technology (SOEC)

The proof: fire protection of the highest quality

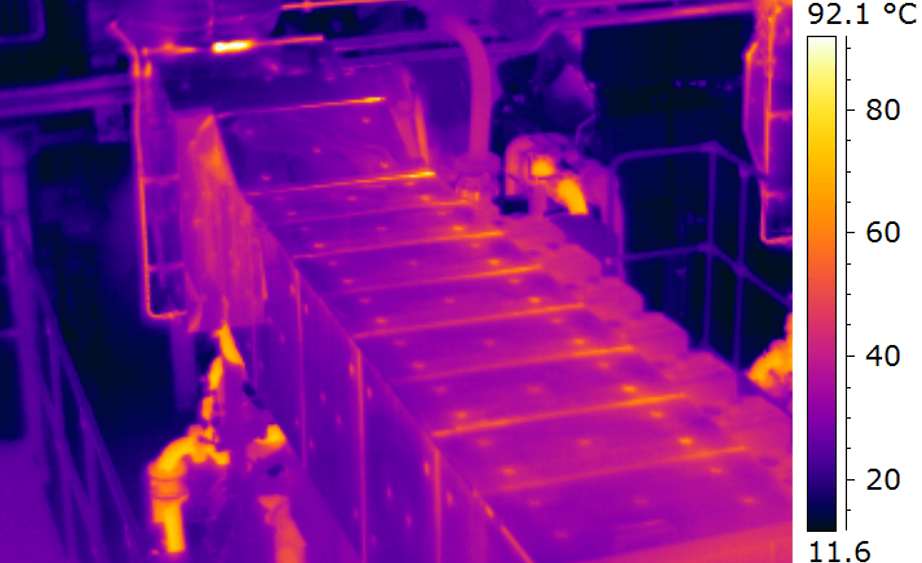

tmax insulation cladding in thermography

With over 45 years of experience as a solution provider in high-temperature insulation, tmax has been able to build a sophisticated research laboratory. In this laboratory, we can prove that our products deliver what they promise by using the latest technologies and broad technical know-how. This includes thermography carried out with our own equipment, which clearly proves that the surface temperatures of temperature-sensitive components are protected from overheating.

Flammable deposits no longer catch fire. The reliability and cost-effectiveness of the machine are therefore increased.

High temperature insulation: no heat, no fire

Three fantastic high-temperature solutions

Unbeatable when combined

A wide product range of different insulation materials allows us to solve any high-temperature challenges.

Metal insulation cladding

- High insulation value

- High durability

- Easy assembly

- Ease of maintenance

Foil Insulation

- Accurate fit, for complex shapes

- Light weight and space saving

- Optional: Water repellent insulation material

- Optional: Reinforced sound insulation

Textile Insulation

- Perfect touch protection

- Quick assembly and disassembly

- Short development times

- Low tooling costs

Combined Insulation

Sometimes, not only one type of insulation is suitable. More and more often, our solutions are as individual as your challenge. We combine the advantages of suitable insulation types and develop an insulation solution specifically tailored to your requirements.